drmoss_ca

Is there a Doctor in the house ?

You have to be pretty far down the rabbit hole to do this, but most of us here understand having an obsession justifies doing whatever it takes. I've been making my own soap for seven years, and it isn't hard. There was a lot of experimentation at first, as I knew I wanted a tallow-style soap (but had no simple access to tallow), and I wanted to recreate the P.160 Tipo Morbido Italian soft shaving soap that was being discontinued about that time. I haven't managed the almond scent, but I have got a soap that has meant my last couple of kilos of P.160 have lain unmolested all these years.

Let's do some basics first. Soap is made by a chemical reaction between a fat and an alkali ('lye'). And, yes, it probably began with a joint of meat dripping fat into the alkaline wood ash of an ancient fire! The fats contain fatty acids of various kinds, which result in different qualities to the soap you make. The fatty acids we are discussing are long(ish) carbon chains ending in a carboxylic acid group (-COOH). They exist in the general form of triglycerides, just like the doctor measures in your blood. This means there are three of them attached to a single anchoring molecule at one end, glycerol/glycerin/glycerine (all the same thing!). I'll attempt some ASCII art:

||/\/\/\/\/\/\/\/\-COOH

||

||/\/\/\/\/\/\/\/\-COOH

||

||/\/\/\/\/\/\/\/\-COOH

The different fatty acids have different chain lengths - the zig-zag bits going off to the right. In the presence of KOH or NaOH, the three chains break off and each join onto a K+ or a Na+, forming a salt, which is a metal ion linked to the acid chain with the last hydrogen knocked off. This leaves us with:

/\/\/\/\/\/\/\/\/\-COOK

and

/\/\/\/\/\/\/\/\/\-COONa

and, as well as three of the above, the

||

||

||

||

||

and that part is the glycerine. All soap contains glycerine when it is made. What we call 'glycerine soap' is exactly that, and it has a low melting point and is thus referred to as 'melt and pour' soap because you can do just that. But real soap manufacturers are crafty, they remove the glycerine from their soaps and sell it for some other purpose, and then mill and dry the remaining soap to make a hard and long lasting soap. Fools like me who think they can make a good shaving soap at home just leave the glycerine in situ, which really means I haven't the faintest idea how to remove it and what would I do with it if I did? Actually, I know exactly what I'd do with it - use it instead of oil on hard Arkansas stones!

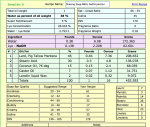

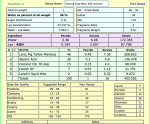

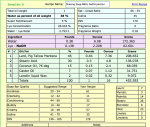

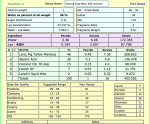

So how do we do this? The lowest form of soap making is the melt and pour method mentioned above. You buy someone else's glycerine soap, melt it, colour it, scent it and pour it into molds and pretend you made soap. We won't go there. We are going to do some chemistry! We will mix alkali and fat and react them together. This can be done at room temperature, in which case it will take a month for the reaction to complete (cold process soap) and if you don't wait you will get alkali burns on your face. Or we can raise the temperature, speed the reaction, and get it all done in a few hours. The soap can be used as soon as it's set. First question then, is how much of what ingredients? There are two alkalis in use, sodium hydroxide (NaOH) which tends to make hard soaps, and potassium hydroxide (KOH) which makes them softer. But it's not just hardness at play, it's bubbliness or latherability, creaminess for cushion, and so on. You may have tried lathering ordinary hand soap with a brush and discovered that most won't work. There's a complicated set of trade-offs between one attribute and another. Then you have to know how much alkali for how much fat. We know those ratios, and they are different for each alkali with each fat. The idea is to use up all the alkali in the reaction, because you don't enjoy alkali burns. You can even put in a bit extra fat, leaving a percentage unsaponified, which we call 'superfat'. There's a very useful online calculator that will do all the hard work for you here. You enter the kind of alkali, the amount of soap you want to make, the percent superfat and pick the fats to use. It tells you how much lye, how much water, how much fat, and gives some hints about the qualities of the soap you are designing. If you want a mix of NaOH and KOH all in one batch, you use the calculator twice and add up all the ingredients. My recipe looks like this - it is half and half sodium and potassium hydroxide, and uses a mixture of lard and stearic acid to simulate tallow, along with some coconut oil, castor oil and lanolin for their special qualities (the lanolin, for example, will not saponify so it becomes my superfat):

Yes, they have modernised the soap calculator a bit since I saved those! So I take all of the ingredients in those two recipes, add them together and I have the amounts I need. For the hot process, you need either a slow cooker, or a double boiler. I make one by placing a saucepan inside my big jam-making pan. The water between means I don't overheat anything as it can't go over 100ºC. The fats are weighed out and placed in the inside pan to melt. The lye is weighed out, and the water is measured. Outdoors, wearing rubber gloves and eye protection, I add the alkali to the water (NOT THE OTHER WAY ROUND! And if you don't know why, it would be better for you to buy soap and not make it.) It will get very hot as it dissolves. Then the alkali solution is added to the melted fats, and a stick blender used to mix them so they react, which happens quite quickly for this recipe. At this point it will look like this:

Now you keep the water simmering in the double boiler, refilling as needed, with a lid on the inner pan to keep the heat in. Periodically use a strip of indicator paper to check the pH of the soap. It will start out strongly alkaline, around pH 12, and you keep cooking until it gets to pH7 -8. This takes 3-4 hours. When you get there, turn off the heat and start measuring the temperature as it cools. We are going to try to scent it. I say try as I'm not very good at this part! Scent oils are cheap and generally strong and a bit nasty. Essential oils are very expensive but less nasty. I'm cheap. All of them are thin and volatile, which is why, and how, they smell - they vaporise. If you add scent oil when the soap is hot, it will flash off as they say, and most bottles will have a flash temperature marked on them. You need the soap to cool below that temperature before you add the oil, or it will just evaporate. BUT, as the soap cools it begins to get hard, and it gets difficult to mix in the oil properly. Let me know if you discover the secret; as I said, I'm not very good at this part. Anyway, I use a gardenia scent as my wife loves it and also because I don't know of any commercial shaving soap scented that way. Gotta be different. When the scent is added and mixed, you pack the rapidly solidifying soap into a mold. This one is wooden and lined with parchment paper:

I leave it overnight to set up properly. The soap I make is not hard like a milled soap, but comes out soft and malleable so it can be pressed into a mug or scuttle. In the morning, you get to cut it into slices:

I stick them in a ziplock bag in a cool place for storage (although lately of each batch I make I get to keep only two bars, and the rest I send to Tim Zowada who likes it and gives it to his friends).

When you calculate the cost of ingredients, each of the slices in the picture costs about $2CDN, so about half the price of a bar of bath soap from a supermarket, and a small fraction of the price of a "proper" shaving soap from Trumper or Truefitt & Hill. I like the product, it makes a thick and creamy kind of lather that suits me well, and more than satisfies my desire to mimic P.160. The shelves of some of my brushes, many of the colognes, and some of the shaving soaps (later numbering over 100 brands) became known as The Shelves of Shame when I discovered I no longer used any of those soaps (never mind the creams stored elsewhere) as they didn't work as well as a decent home made soap!

I also experimented with making other kinds of soap, like this block of olive oil bath soap:

It's not hard to do, and the results are well worth the small amount of effort. I buy my supplies from canwax.com, and I'm sure there are many other suppliers capable of selling you the basic ingredients. Some people turn up their noses when I mention lard as an ingredient. Lard is rendered pig fat. Tallow is rendered beef fat. Tallow is rightly prized as an ingredient in a good shaving soap. Whichever you can find and use, it is all renewable, and if you're eating the bacon or the steak anyway, why not find a use for the rest of the carcass? The pandering of the soap industry to the vegetarians and vegans has simply resulted in Indonesian rain forests being clear cut to make way for palm oil plantations with the result that the orang utan is being driven to extinction and you can't buy a decent functional shaving soap anymore. Make your own; better shaves and the orang utans will thank you!

Let's do some basics first. Soap is made by a chemical reaction between a fat and an alkali ('lye'). And, yes, it probably began with a joint of meat dripping fat into the alkaline wood ash of an ancient fire! The fats contain fatty acids of various kinds, which result in different qualities to the soap you make. The fatty acids we are discussing are long(ish) carbon chains ending in a carboxylic acid group (-COOH). They exist in the general form of triglycerides, just like the doctor measures in your blood. This means there are three of them attached to a single anchoring molecule at one end, glycerol/glycerin/glycerine (all the same thing!). I'll attempt some ASCII art:

||/\/\/\/\/\/\/\/\-COOH

||

||/\/\/\/\/\/\/\/\-COOH

||

||/\/\/\/\/\/\/\/\-COOH

The different fatty acids have different chain lengths - the zig-zag bits going off to the right. In the presence of KOH or NaOH, the three chains break off and each join onto a K+ or a Na+, forming a salt, which is a metal ion linked to the acid chain with the last hydrogen knocked off. This leaves us with:

/\/\/\/\/\/\/\/\/\-COOK

and

/\/\/\/\/\/\/\/\/\-COONa

and, as well as three of the above, the

||

||

||

||

||

and that part is the glycerine. All soap contains glycerine when it is made. What we call 'glycerine soap' is exactly that, and it has a low melting point and is thus referred to as 'melt and pour' soap because you can do just that. But real soap manufacturers are crafty, they remove the glycerine from their soaps and sell it for some other purpose, and then mill and dry the remaining soap to make a hard and long lasting soap. Fools like me who think they can make a good shaving soap at home just leave the glycerine in situ, which really means I haven't the faintest idea how to remove it and what would I do with it if I did? Actually, I know exactly what I'd do with it - use it instead of oil on hard Arkansas stones!

So how do we do this? The lowest form of soap making is the melt and pour method mentioned above. You buy someone else's glycerine soap, melt it, colour it, scent it and pour it into molds and pretend you made soap. We won't go there. We are going to do some chemistry! We will mix alkali and fat and react them together. This can be done at room temperature, in which case it will take a month for the reaction to complete (cold process soap) and if you don't wait you will get alkali burns on your face. Or we can raise the temperature, speed the reaction, and get it all done in a few hours. The soap can be used as soon as it's set. First question then, is how much of what ingredients? There are two alkalis in use, sodium hydroxide (NaOH) which tends to make hard soaps, and potassium hydroxide (KOH) which makes them softer. But it's not just hardness at play, it's bubbliness or latherability, creaminess for cushion, and so on. You may have tried lathering ordinary hand soap with a brush and discovered that most won't work. There's a complicated set of trade-offs between one attribute and another. Then you have to know how much alkali for how much fat. We know those ratios, and they are different for each alkali with each fat. The idea is to use up all the alkali in the reaction, because you don't enjoy alkali burns. You can even put in a bit extra fat, leaving a percentage unsaponified, which we call 'superfat'. There's a very useful online calculator that will do all the hard work for you here. You enter the kind of alkali, the amount of soap you want to make, the percent superfat and pick the fats to use. It tells you how much lye, how much water, how much fat, and gives some hints about the qualities of the soap you are designing. If you want a mix of NaOH and KOH all in one batch, you use the calculator twice and add up all the ingredients. My recipe looks like this - it is half and half sodium and potassium hydroxide, and uses a mixture of lard and stearic acid to simulate tallow, along with some coconut oil, castor oil and lanolin for their special qualities (the lanolin, for example, will not saponify so it becomes my superfat):

Yes, they have modernised the soap calculator a bit since I saved those! So I take all of the ingredients in those two recipes, add them together and I have the amounts I need. For the hot process, you need either a slow cooker, or a double boiler. I make one by placing a saucepan inside my big jam-making pan. The water between means I don't overheat anything as it can't go over 100ºC. The fats are weighed out and placed in the inside pan to melt. The lye is weighed out, and the water is measured. Outdoors, wearing rubber gloves and eye protection, I add the alkali to the water (NOT THE OTHER WAY ROUND! And if you don't know why, it would be better for you to buy soap and not make it.) It will get very hot as it dissolves. Then the alkali solution is added to the melted fats, and a stick blender used to mix them so they react, which happens quite quickly for this recipe. At this point it will look like this:

Now you keep the water simmering in the double boiler, refilling as needed, with a lid on the inner pan to keep the heat in. Periodically use a strip of indicator paper to check the pH of the soap. It will start out strongly alkaline, around pH 12, and you keep cooking until it gets to pH7 -8. This takes 3-4 hours. When you get there, turn off the heat and start measuring the temperature as it cools. We are going to try to scent it. I say try as I'm not very good at this part! Scent oils are cheap and generally strong and a bit nasty. Essential oils are very expensive but less nasty. I'm cheap. All of them are thin and volatile, which is why, and how, they smell - they vaporise. If you add scent oil when the soap is hot, it will flash off as they say, and most bottles will have a flash temperature marked on them. You need the soap to cool below that temperature before you add the oil, or it will just evaporate. BUT, as the soap cools it begins to get hard, and it gets difficult to mix in the oil properly. Let me know if you discover the secret; as I said, I'm not very good at this part. Anyway, I use a gardenia scent as my wife loves it and also because I don't know of any commercial shaving soap scented that way. Gotta be different. When the scent is added and mixed, you pack the rapidly solidifying soap into a mold. This one is wooden and lined with parchment paper:

I leave it overnight to set up properly. The soap I make is not hard like a milled soap, but comes out soft and malleable so it can be pressed into a mug or scuttle. In the morning, you get to cut it into slices:

I stick them in a ziplock bag in a cool place for storage (although lately of each batch I make I get to keep only two bars, and the rest I send to Tim Zowada who likes it and gives it to his friends).

When you calculate the cost of ingredients, each of the slices in the picture costs about $2CDN, so about half the price of a bar of bath soap from a supermarket, and a small fraction of the price of a "proper" shaving soap from Trumper or Truefitt & Hill. I like the product, it makes a thick and creamy kind of lather that suits me well, and more than satisfies my desire to mimic P.160. The shelves of some of my brushes, many of the colognes, and some of the shaving soaps (later numbering over 100 brands) became known as The Shelves of Shame when I discovered I no longer used any of those soaps (never mind the creams stored elsewhere) as they didn't work as well as a decent home made soap!

I also experimented with making other kinds of soap, like this block of olive oil bath soap:

It's not hard to do, and the results are well worth the small amount of effort. I buy my supplies from canwax.com, and I'm sure there are many other suppliers capable of selling you the basic ingredients. Some people turn up their noses when I mention lard as an ingredient. Lard is rendered pig fat. Tallow is rendered beef fat. Tallow is rightly prized as an ingredient in a good shaving soap. Whichever you can find and use, it is all renewable, and if you're eating the bacon or the steak anyway, why not find a use for the rest of the carcass? The pandering of the soap industry to the vegetarians and vegans has simply resulted in Indonesian rain forests being clear cut to make way for palm oil plantations with the result that the orang utan is being driven to extinction and you can't buy a decent functional shaving soap anymore. Make your own; better shaves and the orang utans will thank you!